- +9714 421 8369

- +971 50 379 6862

- sales@deltapower.ae

Show filters

Showing 73–81 of 95 results

See

Silent Type

Silent Check Valves are designed to have drip tight sealing in case of back flow.

Moreover, the valve disc is soft seated, which guarantees complete closure.

Due to its spring mechanism, closure of the valve is obtained before back flow reaches the valve, thereby minimizing the surge conditions.

As a result, Silent Check Valve operates in a fast way and closes silently.

Silent Check Valve body is in globe design to minimize the head loss, and can be installed in any position, flow up or flow down.

Single Chamber & Double Function

Single Chamber Air Release and Vacuum Valves are designed to perform two functions:

1. Venting of large volumes of air on the start-up of the system, while pipelines are filled.

2. Intake of large volumes of air on shut-off of the system, while pipelines are being drained.

Single Chamber & Four Function Non-Slam

Non-Slam Air Release and Vacuum Valves are designed to perform the three functions of Double Chamber Air Release and Vacuum Valves, and an additional damping function to protect the system from a possible water hammer:

1. Venting of large volumes of air on the start-up of the system, while pipelines are filled.

2. Intake of large volumes of air on shut-off of the system, while pipelines are being drained.

3. Discharge of pressurized air pockets during the operation.

4. Prevention of slamming during the operation and the start-up of the system by forming an air cushion in the system.

Solenoid Control

Solenoid Control Valves are simple electrically activated on/off valves that can be of critical importance in controlling flow in every water system.

The electrical signal used to activate the solenoid can be sent from timers, relays, clocks, pressure, level or flow transmitters, etc.

Street Light Column Poles

Our tubular / octagonal steel parallel sided stepped lighting columns are available from 3m-18 m and in a wide range of sizes and strengths.

Our standard columns are designed to BS EN 40 to take a variety of lanterns and brackets and special columns can be designed to your individual requirements.

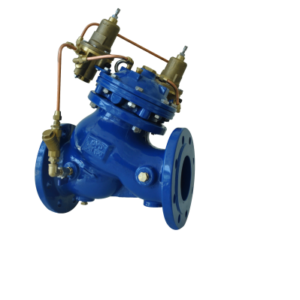

Surge Anticipating

Abrupt pump stopping is followed by a pressure drop as the water column continues traveling along the line.

The returning column hits the closed pump check valve, creating a high pressure surge wave, which travels at up to 4 Mach.

Eliminating such surge requires anticipation and pre-action.

Surge Anticipating Valves react to the pressure drop, accepting the returning column while already open, thus eliminating the surge.

Surge Protection System Pressure vessels

We provide surge analysis and pressure vessels in the piping system to avoid water hammer which can result in the following:

Definition of Water Hammer

The phenomenon of Water Hammer takes place without any advance notice just as blackout, and it causes drastic increase or decrease (negative pressure) of pressure. Thus, it is vital to install equipment to relieve the impact of Water Hammer to secure safe operation of a piping system. The pressure within a piping should be controlled in a certain range during the operation even under an unexpected situation.

Why do a surge(water hammer)analysis necessary?

– Pressure extremes usually occur during a period of transient flow

– Pressures may exceed design limits

– Undesirable conditions occur (low pressures, cavitation, large pressure spikes, etc.)

– High pressure transients break pipes

– Low pressure transients destroy seals

– Low pressure transients may cause health risk

– Evaluate surge protection schemes

Damage of Water Hammer

-Raised pressure in the pipeline causes break of facilities such as pumps, valves, pipes, and supporting structures.

-Vapor cavities causes collapse or heavy shock wave generated in the course of column separation and subsequent return causes break of the pipeline.

– Low pressure in water supply pipeline causes health risk by letting in pollutants from outside.

– Water hammer may cause vibration and noise or make automatic control hard due to abnormal pressure wave.

Based on the surge analysis we provide surge vessel fully tested and certified.

Close