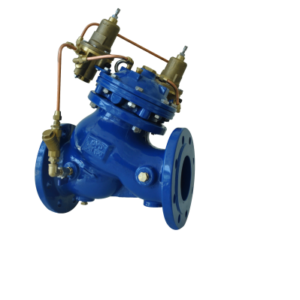

Description

Nominal Size

DN40-DN1200

Nominal Pressure

PN10-63

Face to Face

EN558-1 Series 14-15-3

(DIN 3202 F4-F5-BS)

Accessories

Handwheel

Cap Top

Extension Spindle

Gearbox

Electrical Actuator

Bypass Valve

Position Indicator

Chainwheel

Drain Plug

Jacking Screw

Wedge Guide

Body Material Options

Ductile Iron

Carbon Steel

Stainless Steel

Nickel Aluminum Bronze

Flange Standards

EN 1092/2

BS 4504

BS10E

ANSI

Reviews

There are no reviews yet.