- +9714 421 8369

- +971 50 379 6862

- sales@deltapower.ae

HomeMechanical Products

Show filters

Showing 1–9 of 48 results

See

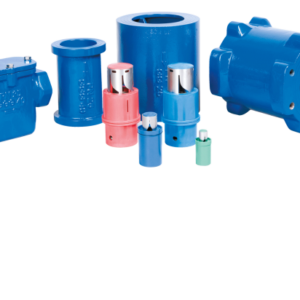

1 Single Chamber & Single Function

Air Release Valves are designed to perform single specified function:

1. Discharge of pressurized air pockets during the operation.

1” Air Valves that are installed especially in the pump stations decrease overall pumping costs by discharging small pressurized air pockets that are slowing down the water flow.

A Type

A Type Irrigation Hydrants have a special closing mechanism enabling gradual flow increase/decrease when the handwheel is turned, preventing slam closure.

Hydrants are available with an optional anti-frost sleeve for deep water networks, and an automatic drainage valve to bleed the body when the hydrant is closed, to prevent frost damages.

Nozzles that are used in hydrant connection have integral pressure regulator and flow limiter in order to provide constant pressure and flow rate to the farmer. Number of nozzles on the body can be increased up to 4 outlets, enabling supply to more than one farmer from a single hydrant.

Aboveground Type

Aboveground Fire Hydrants are made of ductile iron body, valve mechanism, and a spindle that controls the sealing.

When the head of the hydrant is turned counter clockwise, the spindle moves down, sealing the valve at the flow direction. In the reverse action, fire hydrant shuts-off drip tight.

Aboveground Fire Hydrants can be manufactured with 3 different lengths for various pipeline depths.

B Type

B Type Irrigation Hydrants have a special closing mechanism enabling gradual flow increase/decrease when the handwheel is turned, preventing slam closure.

Hydrants are available with an optional anti-frost sleeve for deep water networks, and an automatic drainage valve to bleed the body when the hydrant is closed, to prevent frost damages.

Nozzles that are used in hydrant connection have integral pressure regulator and flow limiter in order to provide constant pressure and flow rate to the farmer. Number of nozzles on the body can be increased up to 2 outlets, enabling supply to more than one farmer from a single hydrant.

Balancing Valves

Balancing Valves are used in HVAC applications for flow regulation.

Cartridge type Dynamic Balancing Valves provide constant flow rate at a predefined pressure range, thereby providing equal heating or cooling opportunity for various users.

Basket Type

Basket Type Strainers are installed to protect system appliances, such as: pumps, flowmeters, control valves or regulating devices.

The main function is to remove foreign matter like leaves, sticks or stones from the pipelines. Foreign particles that can harm crucial appliances in the system are stuck in the filter of the strainer, and the user can check the blockage of the filter by using monometer connections.

In case of a situation where the differential pressure reading is high, the blow-off port is used to remove entrapped debris at the bottom of the body.

Due to its design, Basket Type Strainers feature much bigger trap capacity compared to other types of strainers. Furthermore, service from the top cover enable a more shallow Valve Chamber, thereby decreasing the overall cost of the installation.

C Type

C Type Irrigation Hydrants have a special closing mechanism enabling gradual flow increase/decrease when the handwheel is turned, preventing slam closure.

Hydrants are available with an optional anti-frost sleeve for deep water networks, and an automatic drainage valve to bleed the body when the hydrant is closed, to prevent frost damages.

Nozzles that are used in hydrant connection have integral pressure regulator and flow limiter in order to provide constant pressure and flow rate to the farmer. Number of nozzles on the body can be increased up to 4 outlets, enabling supply to more than one farmer from a single hydrant.

Crepine Type

Crepine Type Strainers are installed in the entrance of pump suction pipes or in a transition from open channel to closed piping.

The main function is to protect the system from foreign matter like leaves, sticks or stones from the pipelines.

Foreign particles that can harm crucial appliances in the system are stuck in the filter of the strainer, thereby preventing entry to the pipeline.

D Type

D Type Irrigation Hydrants have a special closing mechanism enabling gradual flow increase/decrease when the handwheel is turned, preventing slam closure.

Hydrants are available with an optional anti-frost sleeve for deep water networks, and an automatic drainage valve to bleed the body when the hydrant is closed, to prevent frost damages.

D Type Hydrants are used in low pressure applications where the outlets have a flow limiter in order to provide constant flow rate to the farmer. Number of outlets on the body can be increased up to 2 outlets, enabling supply to more than one farmer from a single hydrant.

Close