- +9714 421 8369

- +971 50 379 6862

- sales@deltapower.ae

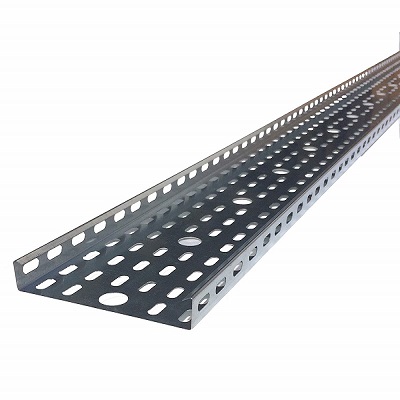

Cable Trays

Cable Trays are support systems used in building electrical wiring. These cable support systems are commonly used to support insulated power and communication cables. Cable trays provide a more preferable alternative to electrical conduit systems and open wiring.

The cable trays which are available in accordingly are as follows:

• Light Duty Cable tray, also known as P Type.

• Medium Duty Cable Tray, also known as M Type.

• Heavy Duty Cable Tray, also known as R Type.

-Light Duty Cable Tray or LDT which are used for light duty applications and are easy to install.

-Medium Duty Cable Tray or MDT is used to provide extra protection and strength to the cable components which improves the life of these cables.

-Heavy Duty Cable Tray or HDT, it is used for extra protection and is installed very easily and have high accessibility.

Reviews

There are no reviews yet.