- +9714 421 8369

- +971 50 379 6862

- sales@deltapower.ae

Show filters

Showing 46–54 of 95 results

See

Level Control

Float controlled valves combine the advantages of excellent hydraulic control valves with the simplicity of mechanical floats.

The ability to separate the main valve from the float enables eliminating most of the installation and maintenance problems associated with mechanical float valves.

Level Control Valve with Modulating Horizontal Float is used to control reservoir filling to maintain constant water level regardless of fluctuating demand.

Lift Type

Lift Check Valves has a disc that lifts up off its seat by higher inlet pressure. When the inlet pressure drops, the disc is closed before the back-flow reaches to the valve, enabling non-slam & drip tight closure.

It has a relatively short valve disc travel resulting in an immediate valve disc closing on no flow conditions, minimizing water hammer and surge conditions.

Lift Check Valve has a center-guided, spring loaded valve disc with a resilient seal, acting over a bronze or stainless steel removable valve seat.

It can be furnished with valve position indicator and electrical limit switches and can be serviced without being removed from the pipeline.

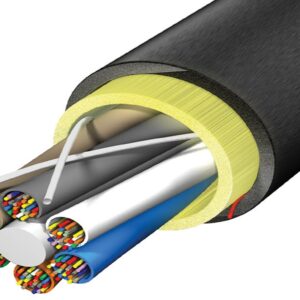

Low Voltage Cables

Application: Power Distribution for Industrial, commercial, institutional and residential purposes.

Types and Sizes: Up to 4 core ranging from 4 sq. mm to 1200 sq. mm

Conductor: Aluminium – Solid, Stranded (Sector/Circular) or Copper – Solid, Stranded (Sector/Circular) or Flexible

Insulation: PVC – Type A, Type C, Polyetheylene, XLPE, ZHFR, LSZH

Inner Sheath: PVC – ST1, HR, FR, FRLS, LSZH

Armour: Galvanized Steel or Aluminium Wire / Strip / Tape

Outer Sheath: PVC – ST1, HR, FR, FRLS, LSZH, XLPO

Low Voltage Switchgear

Our MDB’s are dimensionally accurate and offer hassle-free performance and are well known for their superior quality, durability, high mechanical strength and perfect finishing.

• Design verified power switchgear and control gear assembly as per IEC 61439-2 and type tested for internal errors (arc faults) as per IEC 61641

• Modular sheet steel assembly system with 2 mm thickness and Internal segregation from form 1 to form 4 as per IEC 61439-2 with high level of corrosion resistance

• Epoxy powder coated to RAL 7032/ RAL 7035 and folded construction for high rigidity

• Fully type-tested panels up to 7000A (ASTA Certified) in compliance with all major regulations including DEWA,

MCC Panels

The MCC panels comply with international standards and are available with multiple power stabs that help in supporting high capacity industrial motors as per the client specifications.

• Fully type-tested panels including internal arc fault test

• Form 2, 3 and 4 types of segregations

• Busbar rating up to 7000 A

• Available in fixed and draw out type of design

• Provision of forced ventilation when required

• IP ratings up to IP65

• Front or rear access with pre-fabricated bolts on base for protective devices

• Fault withstand of up to 50KA for 3 Seconds

• Panels in compliance with all international standards

Close